Shaping the Future: Manufacturing Trends for 2025 and Beyond

Shaping the Future: Manufacturing Trends for 2025 and Beyond

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Shaping the Future: Manufacturing Trends for 2025 and Beyond. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Shaping the Future: Manufacturing Trends for 2025 and Beyond

The manufacturing landscape is undergoing a dramatic transformation, driven by technological advancements, evolving consumer demands, and a growing emphasis on sustainability. Trends manufacturing 2025 encapsulates these shifts, painting a picture of a future where automation, data-driven insights, and a focus on human-centered production will define the industry. This exploration delves into the key trends shaping the future of manufacturing, highlighting their significance and potential benefits.

The Technological Revolution: Driving the Evolution of Manufacturing

The heart of trends manufacturing 2025 lies in the rapid adoption of advanced technologies. These advancements are not just automating tasks; they are fundamentally changing how products are designed, manufactured, and delivered.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are revolutionizing manufacturing processes, enabling predictive maintenance, quality control optimization, and intelligent automation. Machine learning algorithms can analyze vast datasets, identifying patterns and predicting potential issues before they arise, leading to increased efficiency and reduced downtime.

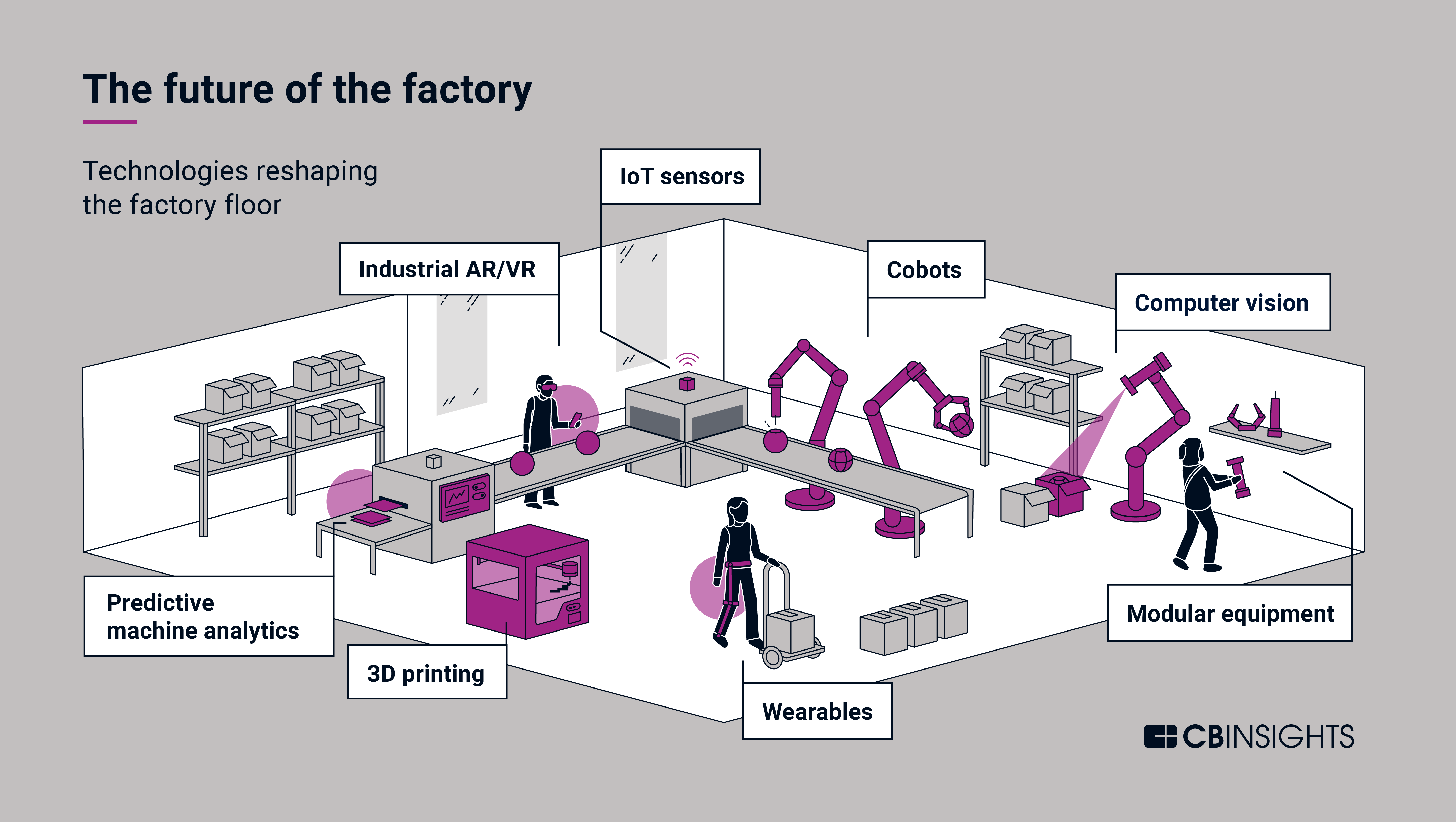

- Internet of Things (IoT): The interconnectedness of devices within a manufacturing environment through IoT empowers real-time data collection and analysis. Sensors embedded in machinery and equipment can monitor performance, identify anomalies, and trigger proactive maintenance actions. This data-driven approach optimizes production processes and ensures seamless operation.

- Robotics and Automation: Robots are increasingly taking over repetitive and hazardous tasks, freeing human workers to focus on more complex and creative endeavors. Collaborative robots (cobots) are designed to work alongside humans, enhancing safety and productivity. This automation trend is transforming manufacturing into a more efficient and safer environment.

- 3D Printing and Additive Manufacturing: 3D printing is revolutionizing product design and production. It allows for rapid prototyping, customized designs, and on-demand manufacturing, enabling manufacturers to create complex geometries and personalized products with increased efficiency. This technology is particularly impactful in niche markets and for producing customized components.

- Cloud Computing and Big Data Analytics: Cloud computing provides scalable and flexible computing resources, enabling manufacturers to store and analyze vast datasets in real-time. Big data analytics allows for identifying trends, optimizing production, and making data-driven decisions that improve efficiency and profitability.

Beyond Technology: The Human Element in the Future of Manufacturing

While technology plays a crucial role in shaping the future of manufacturing, it is essential to recognize the importance of human capital. Trends manufacturing 2025 emphasizes a human-centered approach, where technology empowers workers and enhances their skills.

- Upskilling and Reskilling: The rapid technological advancements necessitate a shift in the skills required for manufacturing jobs. Companies are investing in upskilling and reskilling programs, equipping workers with the knowledge and abilities needed to operate and maintain advanced technologies. This focus on human capital development ensures a smooth transition to a more automated future.

- Collaboration and Knowledge Sharing: The future of manufacturing relies on collaboration and knowledge sharing. Manufacturers are embracing open innovation, fostering partnerships, and engaging in knowledge transfer initiatives to leverage collective expertise and accelerate innovation. This collaborative approach fosters a culture of continuous learning and improvement.

- Employee Well-being and Safety: Trends manufacturing 2025 prioritize employee well-being and safety. Companies are implementing ergonomic designs, promoting workplace safety practices, and creating a positive work environment that fosters employee satisfaction and productivity.

Sustainable Manufacturing: Building a Future for the Planet

Sustainability is no longer a niche concern; it is becoming a core principle for manufacturers. Trends manufacturing 2025 emphasizes environmentally responsible practices, driving innovation and resource efficiency.

- Circular Economy: Manufacturers are embracing circular economy principles, focusing on reducing waste, reusing materials, and extending product lifecycles. This approach minimizes environmental impact and creates a more sustainable manufacturing system.

- Energy Efficiency and Renewable Energy: Manufacturers are actively seeking ways to reduce energy consumption and transition to renewable energy sources. This includes implementing energy-efficient processes, utilizing solar panels, and exploring other sustainable energy options.

- Sustainable Materials: Manufacturers are incorporating sustainable materials into their products, reducing reliance on harmful chemicals and promoting the use of recycled and renewable resources. This commitment to sustainable materials minimizes environmental impact and creates products with a lower carbon footprint.

The Impact of Trends Manufacturing 2025**

The trends shaping the future of manufacturing offer significant benefits, impacting various aspects of the industry:

- Increased Efficiency and Productivity: Automation, data analytics, and optimized processes drive significant improvements in efficiency and productivity, leading to lower costs and increased profitability.

- Enhanced Quality and Innovation: Advanced technologies enable manufacturers to create products with higher quality and precision, while data-driven insights foster innovation and product development.

- Improved Customer Experience: Personalized products, faster delivery times, and enhanced product quality contribute to a more satisfying customer experience.

- Economic Growth and Job Creation: The technological advancements and increased efficiency create new job opportunities and contribute to economic growth.

- Environmental Sustainability: Sustainable practices minimize environmental impact, promoting responsible resource utilization and reducing carbon emissions.

Exploring Related Searches: Deepening the Understanding of Trends Manufacturing 2025**

Understanding the trends shaping the future of manufacturing requires exploring related searches that delve deeper into specific aspects of the industry:

1. Industry 4.0: Industry 4.0 refers to the fourth industrial revolution, characterized by the integration of digital technologies, automation, and data analytics. This concept is closely intertwined with trends manufacturing 2025, as it outlines the technological foundation for the future of manufacturing.

2. Smart Factories: Smart factories are manufacturing facilities equipped with advanced technologies, including AI, IoT, and robotics, enabling real-time data analysis, automated processes, and improved decision-making. This concept exemplifies the practical application of trends manufacturing 2025 in real-world settings.

3. Digital Twins: Digital twins are virtual representations of physical assets, such as machines or products, used for simulation, analysis, and optimization. This technology allows manufacturers to test scenarios, predict performance, and improve decision-making before implementing changes in the real world.

4. Advanced Materials: Advanced materials, such as composites, ceramics, and nanomaterials, offer enhanced properties and performance, enabling manufacturers to create lighter, stronger, and more durable products. The use of these materials is driven by the demand for innovative products and sustainable solutions.

5. Supply Chain Optimization: Supply chain optimization involves leveraging data analytics and advanced technologies to improve the efficiency and effectiveness of supply chains. This includes optimizing inventory management, streamlining logistics, and enhancing collaboration with suppliers.

6. Cybersecurity in Manufacturing: Cybersecurity is crucial in protecting manufacturing systems and data from cyber threats. As manufacturers become more reliant on interconnected technologies, safeguarding sensitive data and ensuring operational security is paramount.

7. Workforce Development for Manufacturing: The future of manufacturing requires a skilled workforce capable of operating and maintaining advanced technologies. This necessitates investments in training programs, upskilling initiatives, and education to prepare workers for the demands of the industry.

8. The Future of Manufacturing Jobs: The automation trend raises questions about the future of manufacturing jobs. While some jobs may be automated, new roles and opportunities will emerge in areas such as data analysis, robotics engineering, and software development.

FAQs: Addressing Common Questions about Trends Manufacturing 2025**

1. What are the biggest challenges facing manufacturers in adopting trends manufacturing 2025?

Adopting trends manufacturing 2025 presents several challenges:

- High Initial Investment: Implementing advanced technologies requires significant financial investments, which can be a barrier for smaller manufacturers.

- Skilled Workforce Shortage: The demand for skilled workers with expertise in advanced technologies is increasing, creating a talent gap that manufacturers need to address.

- Data Security and Privacy Concerns: The reliance on interconnected systems raises concerns about data security and privacy, requiring robust cybersecurity measures.

- Adapting to Rapid Change: The rapid pace of technological advancements necessitates continuous learning and adaptation for both manufacturers and workers.

2. How can manufacturers prepare for the future of manufacturing?

Manufacturers can prepare for the future by:

- Investing in Research and Development: Continuous innovation and exploration of new technologies are crucial for staying ahead of the curve.

- Embracing Digital Transformation: Implementing advanced technologies and embracing a data-driven approach is essential for achieving efficiency and competitiveness.

- Investing in Workforce Development: Upskilling and reskilling programs are crucial for equipping workers with the skills needed for the future of manufacturing.

- Building Strategic Partnerships: Collaborating with technology providers, research institutions, and other stakeholders can accelerate innovation and knowledge sharing.

3. What are the potential benefits of adopting trends manufacturing 2025?

Adopting trends manufacturing 2025 offers numerous benefits:

- Increased Efficiency and Productivity: Automation and data-driven insights lead to significant improvements in efficiency and productivity, reducing costs and increasing profitability.

- Enhanced Product Quality and Innovation: Advanced technologies enable manufacturers to create products with higher quality and precision, fostering innovation and new product development.

- Improved Customer Experience: Personalized products, faster delivery times, and enhanced product quality contribute to a more satisfying customer experience.

- Economic Growth and Job Creation: The technological advancements and increased efficiency create new job opportunities and contribute to economic growth.

- Environmental Sustainability: Sustainable practices minimize environmental impact, promoting responsible resource utilization and reducing carbon emissions.

4. How will trends manufacturing 2025 impact the manufacturing workforce?

Trends manufacturing 2025 will significantly impact the manufacturing workforce:

- Job displacement: Some jobs may be automated, requiring workers to adapt to new roles or reskill.

- New job opportunities: New roles will emerge in areas such as data analysis, robotics engineering, and software development.

- Increased demand for skilled workers: Manufacturers will need skilled workers with expertise in advanced technologies, creating a demand for specialized skills.

- Importance of human-centered design: Trends manufacturing 2025 emphasizes the importance of human capital, focusing on employee well-being, safety, and upskilling initiatives.

Tips for Manufacturers: Navigating the Future of Manufacturing

- Embrace a data-driven culture: Utilize data analytics to gain insights into operations, optimize processes, and make informed decisions.

- Invest in employee training and development: Ensure your workforce is equipped with the skills needed to operate and maintain advanced technologies.

- Foster a culture of innovation: Encourage experimentation, collaboration, and the exploration of new ideas to drive innovation and stay ahead of the curve.

- Prioritize sustainability: Implement environmentally responsible practices, reducing waste, conserving resources, and minimizing your environmental footprint.

- Embrace strategic partnerships: Collaborate with technology providers, research institutions, and other stakeholders to leverage collective expertise and accelerate innovation.

Conclusion: Embracing the Future of Manufacturing

Trends manufacturing 2025 signifies a pivotal moment in the evolution of manufacturing. By embracing technological advancements, prioritizing human capital, and promoting sustainable practices, manufacturers can position themselves for success in a rapidly changing industry. The future of manufacturing is one of innovation, efficiency, and sustainability, offering immense opportunities for those who are prepared to adapt and embrace the changes ahead.

Closure

Thus, we hope this article has provided valuable insights into Shaping the Future: Manufacturing Trends for 2025 and Beyond. We appreciate your attention to our article. See you in our next article!